1- Compression Testing Machine:

.jpg)

2- Universal Testing Machine:

A machine which is used to determine the tensile strength and compressive strength of the material is called universal testing machine. It is named universal testing machine based on a fact that it can perform many standard tensile and compression test on material, components and structure. These machines range from very small table top system to once with over 53 MN capacity. Famous brands or bricks machine are Shimadzu, Instron, Sates.3- Concrete Creep Testing Machine:

It is an instrument which is used to determine the creep in the concrete. Creep is the permanent deformation in the concrete due to the influence of the long term loading creep does not necessarily because concrete to fail or break apart but it can cause change in shape or increased deflection in the concrete structure.

It is an instrument which is used to determine the creep in the concrete. Creep is the permanent deformation in the concrete due to the influence of the long term loading creep does not necessarily because concrete to fail or break apart but it can cause change in shape or increased deflection in the concrete structure.4- Lathe Machine:

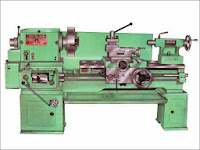

A lathe machine is a tool which rotates the work piece on its axis to perform various operations such as cutting, sanding or drilling to create an object which has symmetry about an axis of rotation. A lathe may or may not have a stand which sits on the floor and elevates. The lathe bed to a working height. Wood working lathe metal working lathe glass working lathe etc. are same common categories of lathe machine.

A lathe machine is a tool which rotates the work piece on its axis to perform various operations such as cutting, sanding or drilling to create an object which has symmetry about an axis of rotation. A lathe may or may not have a stand which sits on the floor and elevates. The lathe bed to a working height. Wood working lathe metal working lathe glass working lathe etc. are same common categories of lathe machine.5- Sample Preparing Table:

A material plate form which is used for the preparation of the concrete sample in the lab is called the sample preparing table. The surface of the table should be levelled and very smooth so that fine and good quality samples can be prepared.

6- Weighing Balance:

A weighing balance is a measuring instrument form determining the weight or mass of the object the lab must be equipment with very precise and activate weighing balance. Weighing balance can be digital or analogue tube type. It usually has two scales.

A weighing balance is a measuring instrument form determining the weight or mass of the object the lab must be equipment with very precise and activate weighing balance. Weighing balance can be digital or analogue tube type. It usually has two scales.

i. Kilogram KG.

ii. Pounds LBS.

ii. Pounds LBS.

The balance must have the capacity to weigh at least 50 KG material at a time.

7- Cement Storage Boxes:

8- Cement Storage Drums:

These are metallic drums which are made for storage of cement.

9- Aggregates Carriers:

These are the buckets for the storage of the aggregates. These are two types of aggregates.

These are the buckets for the storage of the aggregates. These are two types of aggregates.i. Sand.

ii. Crush.

Sand and crush both are further many types. There must be each type of aggregates present in the lab separately.

10- Tap Water:

Connections of the tape water vary essential for the civil engineering materials lab. Since, it is used in making of concrete and washing of equipments.

A concrete mixer is a machine that homogeneously combines cement, sand, gravel and water to form concrete. A typical concrete mixer use a revolving drum to mixes the components. For smaller volume works portable concrete mixer is often used so that the concrete can be made at the construction site. These are different capacity mixer available in the market varying from 0.75-9m3.

12- Wheel Barrow:

A wheel barrow is a small hand propelled vehicle with just one wheel. It is design to be push and guided by a single person. Using two handles to its rear. It is use to transport materials with in the lab.13- Slump Cone:

The mould which is used to easy out the workability test on concrete is called slump cone. It is opened at both ends and provided with handles. The concrete slump test is an implicit test that measures the workability of fresh concrete.

.jpg)

14- Workability Tester:

It is an apparatus which is used for the determination of the workability of the concrete..jpg)

15- Vebe Timer:

It is an instrument which is used to determine the workability of concrete in term of vebe time using slump cone. It is more scientific test then the slump test.

16- Vibrating Table:

It is a machine which is used for the determination of the compaction of the concrete.

17- Vibrating Machine:

It is a machine which is used to check the strength of the concrete.

18- Concrete Permeability Apparatus:

This is an apparatus which is used for the determination of the permeability of the concrete.

19- Compact Value Test:

This is an apparatus which is used to determine compact value of the coarse aggregate in term of toughness.

20- Concrete Cutter:

It is a machine which is used to concrete any irregular concrete block into a regular shape. Expensive safety is required in order to operate this machine..jpg)

21- Separator:

It is used for the grading of concrete by sieves.

22- Curing Tank:

These are the tanks which are used for the curing of the concrete. A curing tank may or may not have showers over it to cure the huge pieces of the concrete.

23- Thermostatic Curing Tank:

It is a curing tank which is used to cure the concrete samples at a very controlled the temperature.24- Moulds:

There are different shape moulds which are used for the moulding of concrete in different shapes. Most common type of mould are cube moulds having dimensions 6×6×6 and cylindrical mould having diameter 150mm height 330mm cube moulds are usually used by British standard (BS) vile cylindrical sample are used by American standard (ASTM).there are other shape of moulds as well for example bee moulds.

25- Samples:

These are sample of different aggregates used in the civil Engineering materials lab for example Ravi sand, Chenab sand, Margala crush and Sargodha crush etc.

.jpg)

.jpg)

.jpg)

The difference between initial and final reading will give the actual energy to fracture the specimen. martindale abrasion tester

ReplyDeleteThanks you so much for approaching, keep supporting by sharing our post on your social media groups and pages.

DeleteThanks you for sharing this unique useful information content with us. Really awesome work. keep on blogging Concrete Testing Tools

ReplyDeleteThanks you so much for approaching, keep supporting by sharing our post on your social media groups and pages.

DeleteNice post! This is a very nice blog that I will definitively come back to more times this year! Thanks for informative post. pull force gauge

ReplyDeleteThanks you so much for approaching, keep supporting by sharing our post on your social media groups and pages.

DeleteThanks you so much for approaching, keep supporting by sharing our post on your social media groups and pages.

ReplyDeleteThanks you so much for approaching, keep supporting by sharing our post on your social media groups and pages.

ReplyDeleteThanks you so much for approaching, keep supporting by sharing our post on your social media groups and pages.

ReplyDeleteBenny Industries’ Automatic Hydraulic Pallet Bricks Machine delivers high-strength, uniform bricks using advanced hydraulic compression technology. Built for continuous heavy-duty performance, it automates feeding, molding, and pallet handling. The machine ensures faster production, reduced labor, and consistent quality—making it an ideal solution for modern brick manufacturing units. Automatic Hydraulic Pallet Bricks Machine

ReplyDelete